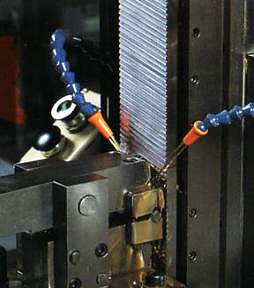

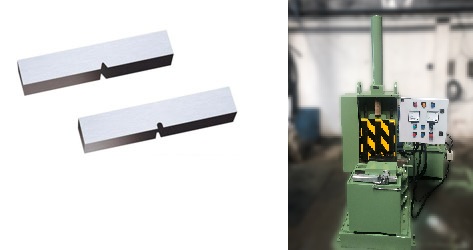

BROACHING MACHINE

High productivity and precision components is the need of the hour. Broaching is the most simple and

highly productive Metal cutting technology process.

Our Broaching Machines are Robust and Rigid in Design as this operation produces vibrations. Roughing,

Semi Finishing and Finishing of the components is done in just unit pass seconds.

Majorly used for internal broaching of gears, internal splines, key-way, bore, routers, couplings, grooves, specific profiles, sprockets, levers, etc. We offer Broaching Machines with the option of an auto loading-unloading facility. Broaching is extensively used in Automotive and Heavy Engineering industries and Die Casting Industries for finer details. It is also used for broaching of external surfaces like matching surfaces of connecting rods, steering racks,etc.

We manufacture

Vertical,

Horizontal,

Table-Up,

Helical and Surface Broaching Machines right

from the scratch according to the Clients need and offer the most efficient Engineering Solutions to

them.

GET A QUOTE